This time we’re bringing you a fascinating look at the connection between Healey Dell and World War Two. This blog has been written by Alan Rawsterne, a research volunteer for SVR who took part in our local history research workshops at Whitworth Museum last year. Alan is also Secretary of the Rooley Moor Neighbourhood Forum. Read on to find out about the Ministry of Supply and its valley based munitions factory…

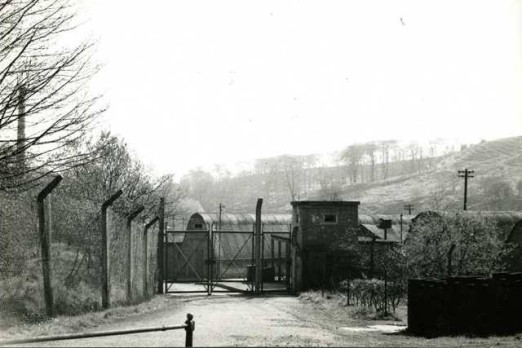

Entrance to Healey Hall Mill Munitions Filling Factory – Photo courtesy of David Wild

Entrance to Healey Hall Mill Munitions Filling Factory – Photo courtesy of David Wild

Hidden in plain sight in a quiet corner of Healey Dell Nature Reserve is a reminder of the Second Word War that is slowly returning back to nature.

Background

In the late 1930’s and up to the outbreak of the Second World War in 1939, the British government developed a strategy to enhance the capacity of three existing Royal Munitions factories and to disperse production of armaments and munitions away from major cities that were considered vulnerable to bombing from the air.

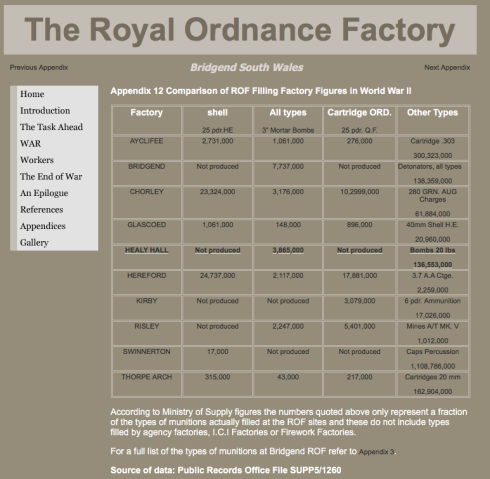

The Ministry of Supply (MoS) built a number of Royal Ordnance Factories (ROF) and satellite factories. ROF Chorley (Filling Factory No. 1) and ROF Bridgend (Filling Factory No. 2) were the two largest filling factories and would replace the Royal Filling Factory located at the Royal Arsenal, Woolwich. Before construction of the two new factories was completed it was realised they would not have capacity to meet the combined British and Commonwealth forces need for ammunition. In total twenty government-owned filling factories were planned but only sixteen were built (see Appendix 1) and none were as large or employed as many people as ROF Chorley and ROF Bridgend.

Healey Hall Mill Munitions Filling Factory

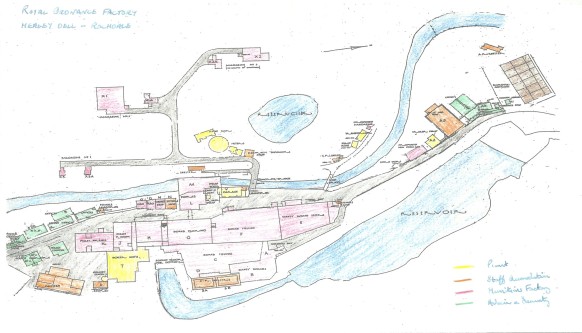

In 1941 an explosives filling factory was established at Healey Hall Mill in Healey Dell, Rochdale. It was designated as an assisted factory with guidance provided by the Royal Ordnance Factory a t Chorley. See Appendix 2 for the site plan.

t Chorley. See Appendix 2 for the site plan.

Opened in 1941 and closed two years later, ROF Healey Hall Mill Munitions Filling Factory filled 136 million 20-lb* bombs for the RAF and 4 million mortar bombs** for the Army. Rumour has it the site was ‘moth balled’ into the 1950’s ready to be brought back into production if the Cold War escalated

*The 20-lb bomb was probably a fragmentation bomb, which was used principally against personnel. It was nose fused and probably fitted with a standard tail for purposes of stabilisation. Fragmentation bombs were generally painted dark green overall with a red band and a light green band around the nose end. Note: The photos above show a British 20-lb high explosive filled bomb, which were originally painted yellow by the British. The change to dark green was made later.

**A mortar is an indirect weapon that fires explosive projectiles known as (mortar) bombs at low velocities, short ranges and high-arching ballistic trajectories. Photo shows WWII British 3” Mortar.

What was a Filling Factory?

A filling factory was a munitions factory that specialised in filling various munitions, such as bombs, shells, cartridges, pyrotechnics, screening smokes (obscurants for the protection of industrial and military objectives against aircraft), etc. The majority of employees were women.

During World War II the factories belonged to the Ministry of Supply (MoS) and were known as a Royal Filling Factory (RFF), or a Royal Ordnance Factory (ROF). Fireworks manufacturers also became part of the filling factory network and undertook the filling of screening smokes and other pyrotechnic devices. Filling factories were part of the Royal Ordnance Factory organisation and Healey Hall was designated as an assisted factory with guidance provided by the Royal Ordnance Factory at Chorley.

Working in a Filling Factory

Around 950,000 British women worked in munitions factories during the Second World War. Eunice Hutt from Rochdale recorded her memories about working at the Healey Hall munitions factory in BBC’s online archive, WW2 People’s War****

“I was 19 years old at the start of the war. I decided to work on the munitions rather than go into the forces. I was living in Lancashire, and I worked in a factory in Healey Dell near Rochdale, making Mortar bombs. We worked in a factory; it was like a big shed with all different rooms. We worked on an assembly line. We sat on either side of a long table and each did a bit of everything towards making the bomb. We changed places every shift so that the job didn’t become too monotonous. The explosives were put in at the very end. There was once an explosion but fortunately nobody was injured.

Healey Dell was a lovely place and the bombers couldn’t see the factory. When the bombers went over we just held our breath to see if they would drop a bomb. They didn’t and I’m still here to tell the tale! We sang a lot to the radio programme ‘music while you work’. We worked a fortnight on days and a fortnight on nights for £3.2.6d. I stayed all during the war and they wrapped up the firm after the war. I then went back to my old job working as a machinist in a clothing factory.”

****Source: WW2 People’s War is an online archive of wartime memories contributed by members of the public and gathered by the BBC. The archive can be found here.

Factory Production Line

Organisation

Explosive ROF’s manufactured TNT, RDX and propellants such as cordite.

Engineering ROF’s, private steel works and forging companies manufactured shells and gun cartridges. It is believed that the empty brass cartridge cases for small arms were made at Small Arms Ammunition Factories.

Transportation

Trains were used to transport raw materials to the filling factories, possibly four siding were installed east of the Facit Branch to serve the Healey Hall factory. There were trains to ROF Chorley from Wigan stations and anecdotal evidence suggests that a daily train for workers in the Healey Hall factory travelled each way between the Wigan area and Broadley Station. The Healey Hall sidings were closed after the war, and a plan was issued in 1946 for the recovery of the rails. The area formerly occupied by the sidings is still visible though covered by woodland.

Raw Materials

Filling Factories used materials such as TNT (trinitrotoluene), which is a high explosive derived from toluene that sometimes caused poisoning in those who worked with it. RDX (cyclotrimethylenetrinitramine) is a white solid organic compound without smell or taste and is a more energetic explosive than TNT.

Process

High explosives, such as TNT, had to be heated to melt them and the liquid was poured hot into heated shell cases. Care had to be taken to ensure that there were no voids in the poured explosive charge as this could lead to the shell detonating in the gun barrel during firing.

Filling factories produced their own pyrotechnics, such as fuses and screening smokes; as many of these were sensitive materials. They were then filled or assembled directly into the munitions. They also would have sewn cotton bags for filling with primer composition or cordite charges.

Design

Filling factories had a large number of buildings that were grouped for the filling of munitions. Explosives magazines were required by each group to store the incoming explosive materials and to store the outgoing filled shells or gun cartridges, which were usually packed in ammunition boxes. Storage buildings were also needed on each ‘group’ to store the incoming empty shells and the empty ammunition boxes.

Magazine

For safety purposes, munitions were segregated into different compatibility groups. A filling factory would generally fill several different groups of munitions and these groups would be located in different geographical areas within the danger area of the filling factory.

Safety considerations were paramount. The design, style and spacing of individual production buildings meant that they were separated by wide open spaces, or depending on the application approximately 20 feet (6 m) high grassed embankments and extremely thick reinforced concrete walls.

Building Groups

Group 1: Initiators, such as caps and detonators for primers and fuses

Group 2: Fuse pellets, exploder pellets, exploder bags

Group 3: Filling of fuses

Group 4: Blending of gunpowder’s for time fuses

Group 5: Filling of cartridges, such as filling cordite into cloth bags or into brass cartridge cases

Group 6: Manufacture of smoke producing compositions

Group 7: Small arms filling

Group 8: Filling of shells or bombs

Group 9: Large magazines, filled ammunition awaiting dispatch

In addition, a filling factory would have provision for limited proofing and testing of its munitions; and burning gr ounds for disposal of waste explosive material.

ounds for disposal of waste explosive material.

There is evidence of a large number of Nissen Huts at ROF Healey Hall Mill, which would probably have been used for storage; the lack of windows in the remaining derelict huts suggests they were not intended to house personnel.

Healey Hall Mill Munitions Filling Factory – Nissen Hut Bases – Photo courtesy of David Pheasey

Other Buildings

Outside of this Danger Area, but still within the factory site, would be located:

- Administration offices

- Laboratories

- Pay offices

- Workshops

- Medical centre

- Changing rooms

- Contraband storage (for items prohibited in the Danger Areas, e.g. matches, tobacco, etc.)

- Police station and search rooms

- Canteens (Healey Hall Mill was segregated for male and female)

- Toilets

- Air raid shelters

- Pill-Boxes

- Electrical Transformer

- Pump house for water

- Septic tank and filters

Pill box

Conclusion

ROF Healey Hall Mill Munitions Filling Factory is a unique survivor from the Second World War and offers an insight into one aspect of the war effort. The site has potential as an education facility, but perhaps nature should be allowed to reclaim it.

Enjoyed reading this? This is just one of the many stories that make up the shared heritage of the Spodden Valley. Why not join the Spodden Valley Revealed Research Team and be a part of a discussion group to help bring to life more stories like this one. Contact Faye for more details or visit our website for more information about the project.

Appendix Contents

- Appendix 1 – List of WW2 ROF Filling Factories

- Appendix 2 – ROF Healey Hall Mill – Site Plan, and

- Appendix 3 – ROF Healey Hall Mill – Buildings

—————————————————————————————————————————————-

Appendix 1

List of Second World War ROF Filling Factories

Twenty World War II Filling Factories were planned, but only 16 were built. The two largest UK Filling Factories were:

- ROF Chorley, (Filling Factory No. 1);

- ROF Bridgend, (Filling Factory No. 2).

The other filling factories were:

- ROF Glascoed, (Filling Factory No. 3).

- ROF Rotherwas, (Filling Factory No. 4) This was a re-opened WW1 National Filling Factory

- ROF Swynnerton (Filling Factory No. 5).

- ROF Risley, (Filling Factory No. 6).

- ROF Kirkby, (Filling Factory No. 7).

- ROF Aycliffe, (Filling Factory No. 8).

- ROF Thorp Arch (Filling Factory No. 9).

- ROF Queniborough, (Filling Factory No. 10).

- ROF Brackla, (Filling Factory No. 11).

- ROF Swindon (Wootton Bassett), (Factory No. 12). *

- ROF Macclesfield, (Factory No. 13). *

- ROF Ruddington, (Filling Factory No. 14).

- ROF Walsall, (Filling Factory No. 15).

- ROF Elstow, (Filling Factory No. 16).

- ROF Featherstone, (Filling Factory No. 17).

- ROF Burghfield, (Filling Factory No. 18) (later part of the Atomic Weapons Establishment (AWE)).

- ROF Tutbury, (Factory No. 19) *

- ROF Northampton, (Factory No. 20) *

(Asterisked factories Nos. 12, 13, 19 and 20 were planned, numbers assigned, but not built.)

Appendix 2

ROF Healey Hall Mill – Site Plan

Appendix 3

ROF Healey Hall Mill – Buildings

Magazine NO 1

Magazine NO 2

Magazine NO 3

Blast Wall

Air Raid Shelters

Canteen

Electrical Engineers Shop

Electrical Transformer

Ladies Toilet

Nissen Hut

Healey Hall Mill Munitions Filling Factory – Nissen Hut Bases – Photo courtesy of David Pheasey

Perimeter Fence

Pill boxes

Police Station

Proposed Magazine

Pump House 1 and 2

Sewage Treatment